Enhancing Manufacturing Precision Through High-Watt Blue Diode Laser Module Technology

Speed and scale used to be the most important things in modern manufacturing, but now precision and adaptability are what set companies apart. Industries today rely on cutting-edge instruments that provide microscopic accuracy without sacrificing efficiency in electronics, automotive, and sophisticated materials production. One such improvement is the Blue Diode Laser, which is noted for its better absorption properties, especially when working with reflective materials like copper and aluminum. This incredibly focused laser technology is now an important part of applications that need precise detail and consistent performance on every run.

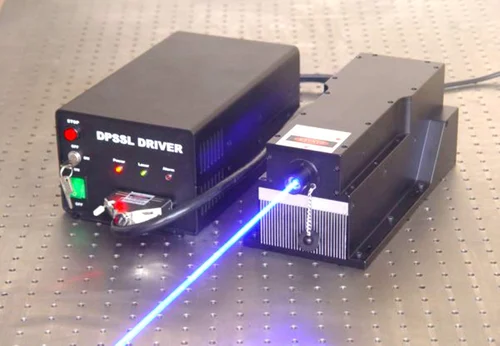

Unmatched Power for Fine Detail

High-watt blue diode modules give processes that need very precise tolerances a lot of power. Blue light lasers work better on lighter and more reflective materials than typical infrared lasers do. This benefit cuts down on material waste and speeds up production without losing any detail. The outcome is cleaner cuts, better welds, and a lot more work getting done on production lines. In fields like microelectronics and precision automobile parts, where consistency is a must, these benefits are especially important. These modules are also easier to add to complicated machines and robotic systems because they are small. They can be easily added to assembly lines and automated machines without causing too much trouble. This gives manufacturers the ability to change or increase production without having to completely overhaul their systems.

Versatility Across Key Industries

The Blue Diode Laser technology can be used in different fields. These lasers help make sure that tab welding and sealing are done correctly in battery production, especially for electric cars. They also don’t heat up sensitive materials too much. In the making of medical devices, they help with micro-welding and structuring small, precise portions where mistakes made by people could lead to serious problems. Blue lasers are utilized for jobs including constructing circuit boards, stripping wires, and labeling components in consumer electronics. These are all operations that benefit from their pinpoint accuracy and low heat output. Also, this technology helps businesses that need a lot of customization, like aerospace and telecommunications, make short runs of high-precision parts without having to wait for tools. It is a very important tool for prototyping and small-batch manufacturing since it can work with a wide range of materials and quickly change designs.

Performance Meets Operational Efficiency

As manufacturing moves toward smarter, more connected ecosystems, laser module technology needs to work with operations that are based on data. AI systems, vision technologies, and automated inspection tools are currently being used with blue diode modules to provide real-time quality assurance and adaptive process control. This changes the laser from a simple cutting or welding instrument into a smart, responsive part of the manufacturing system.

Manufacturers who use these modules should expect to see real improvements, such as fewer failures, shorter cycle times, and lower energy costs. These results show that high-watt blue diode technology is more than simply a tool; it’s a change. It helps manufacturers improve their operations on a very small scale while still supporting the larger aims of scalability, quality, and innovation in industrial design.